Premier Alchem Industries is engaged in of a wide range of metal finishing manufacturingSurface pre-treatment chemicals since from 1985. The company has modern facilities like a well equipped laboratory and production capacity and well trained qualified personnel. Presently the company has a vast approach in the field of Home appliances, Electronics & electrical, automotive and other miscellaneous industries. Our presence through the various product lines allows us to serve industries across most segments in India. PAI is delivering to customer to meet their expectations through continuous innovation and technical services. Our aim to offer a value added product with top quality processes, on-time deliveries and excellent technical service.

COMPANY PROFILE

Premier Alchem Industries is engaged in manufacturing of a wide range of metal finishing Surface pre-treatment chemicals since from 1985.

SURFACE PRE-TREATMENT CHEMICALS

Cleaning / degreasing chemicalsDerusting / descaling chemicalsSurface Activation chemicalsDi and Tri-cation Phosphating ChemicalsSpecial Cleaner Coaters

Manganese Phosphating ChemicalsWire drawing chemicalsIron Phosphating chemicalsPassivation Chemicals-Cr based/Cr freeABS pre-treatment for painting

Forging Lubricant (cold forming) chemicalsSpecial Conversion Coating for Al & its alloys3in1 chemicalsChromatizing Chemicals

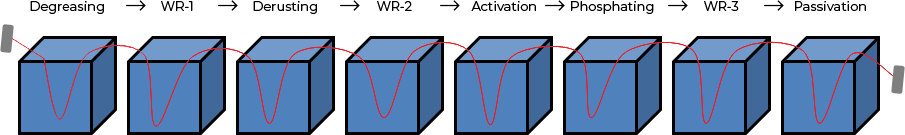

ZINC PHOSPHATING PROCESS

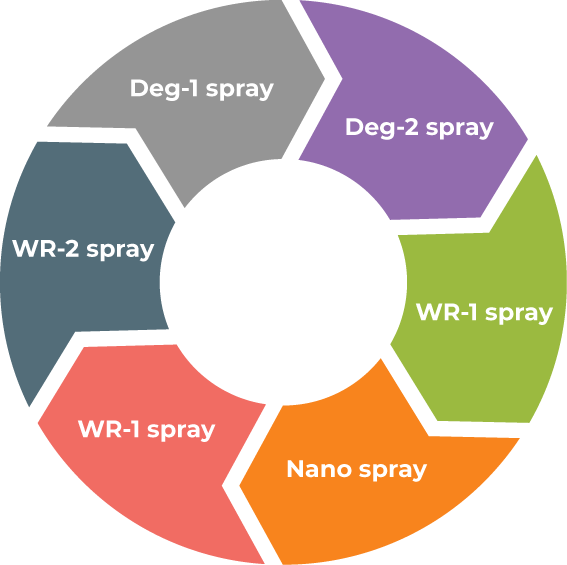

Zinc phosphating is a conversion coating process which resist corrosion & provides adhesion for paint finish. We offer a wide range of products from conventional zinc phosphating to new innovation Nanotechnology. We provide a high performance processes for conversion coating as per customer's specific requirements. In general, following process may be adopted for zinc phosphate process-

Pre-cleaning : To remove excessive oil, dust & foreign particles from the surfaceDe-greasing : To remove complete oil, grease from the surafceWater RinsingWater Rinsing

De-rusting : To remove rust from metal surfaceWater RinsingWater Rinsingurface Activation

PhosphatingWater RinsingWater RinsingPassivationDry Off

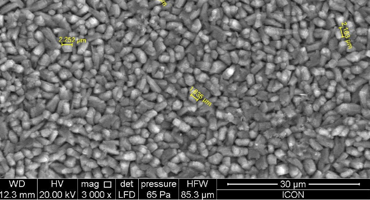

Zinc Phosphate coating

NANOTECHNOLOGY CHEMICAL

Nanotechnology is a Zr based pre-treatment process for multi-metals. It Can be utilized in operations processing a wide range of steel, galvanized steel and aluminium alloys. It is the replacement of conventional zinc-phosphate systems. This unique system will enhance the performance of most paint systems. Application by spray and immersion.

Pre-cleaning : To remove excessive oil, dust & foreign particles from the surface.De-greasing : To remove complete oil, grease from the surafceWater Rinsing

Water RinsingNanotechnology CoatingWater Rinsing

Water RinsingDry Off

Nanotechnology is a new innovation chemical, which applied before painting to parts that contains multi-metals together such as steel, galvanized steel and aluminum, meet customers requirement in energy conservation and environmentally friendly.

Environmental friendlyReducing the amount of heavy metals as compared to Zinc phosphate process.Reduce the cost of wastewater treatmentSludge generation as an industrial waste is negligibleShorten process lengthDerusting, surface activation, passivation stages are skipped as compared to Zinc phosphate process.

LUBRICANTS (COLD FORMING)

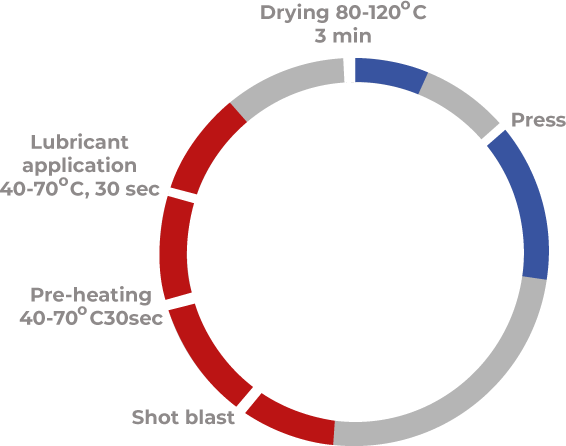

Conventional of cold forming process using Zinc Phosphate chemical and lubricant which is need several production steps that waste a lot of energy and release wastewater after process.

Corolubeis a non-reactive lubricant for cold forming of steel, stainless and non-ferrous.Excellent lubrication within single immersion process and dryingEnvironmental friendly waterborne lubricant chemical with no wastes from processEasy to control the lubricant bath

PAINT STRIPPER

Paint Stripper (RANG REMOVER) is an excellent composition for removal of paint from the surfaces. The paints can be removed either of powder coated, electrodeposition or liquid painting. Paint stripper reacts with the paint within few minutes to peel off paint film. Paint removers are widely used by automotive and non automotive industries for their rework processes of rejected or inferior paint finish articles. Paint Stripper is available in the form of liquid, semi liquid or in jelly form as required by customer’s applications. PREMIER ALCHEM INDUSTRIES manufacturing the alkaline paint stripper which is more safer than acidic paint stripper. This type of alkaline paint stripper has an advantage of delayed rust generation on steel surfaces after paint removal. Paint Stipper can be used to remove paint from pipe lines, motor vans, cars, jeeps, scooters, panel boards, furnitures etc. or whereever paint has to be removed.

AEROSOL-RUST REMOVER/BOLT OPENER

FEROLENE is an unique formulation of chemicals having variety of applications. FEROLENE is a rust remover, loosening oil, polishing agent & helps in cleaning of cardonised parts and spark plug. It is also helpful in degreasing, removing carbon & tar from the metal surfaces and lubricating moving parts. FEROLENE has tremendous domestic applications as well. It helps in quicker & easier opening of rusted metal parts. During maintenance , it saves energy and time without affecting metal surfaces i.e. iron, aluminium, brass, copper & other alloys.FEROLENE self spreads & lubricates difficult joints and non approachable parts. i.e. springs, hinges, joints, rusty locks, nuts & bolts or bound metal parts. FEROLENE due to its high dissolution capacity removes carbon, grease & oils from moving parts in automobiles, railways, aviation and shipping industry. FEROLENE solvency power is effective in polishing metal parts, glass & metal surfaces. It gives a protective coating to metal surfaces and prevents corrosion.FEROLENE is fast in action in opening of fasten metal parts like nuts, bolts, screws, joints in reactors, motor pumps, refrigeration & cooling system lines. FEROLENE can be applied by dipping, cotton buds, brush, direct drops or by spray depending upon the nature & extent of rust application varies. After application, it penetrates rusted metal parts & loosen it. Penetration time may range from 5-20 minutes. For specific purposes even overnight dipping or application recommended. Longer exposure gives sufficient time to enter all the parts & loosen it.

WHY WE?

GET IN TOUCH WITH US

Address

Office & Factory- 93/10A, Shreeji Ind. Est. GIDC Makarpura,Vadodara-390010, Gujrat (India)